Trash

When pursing a Leadership in Energy and Environmental Design (LEED) certification for new construction, as the Scott Arboretum is doing with the Wister Center, even the trash plays an important role. The program is called job-site recycling and recycles all materials from the construction of the Wister Center. This includes all the demolition material from the destruction of the original Wister Greenhouse.

A container of commingled material from Wister Center construction site being dumped at the recycling center. photo credit: A. Golen

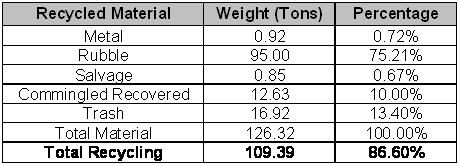

The goal of the program is to divert 75% of the project waste from landfills. Each month we receive a report from W. S. Cumby & Sons, our general contractor, on the amount recycled from the site.

As of July 6, 2009, 109.39 tons of material have been recycled. 86.6% of the project’s waste has been diverted from landfills.

Specific materials are recycled in various manors.

- Metal (steel) waste is processed (shredded) and cleaned before being transported to a mill for recycling

- Wood is separated into reusable pieces, clean wood and B-wood (painted and varnished wood). Reusable wood is sent on to pallet and crate manufacturers that reclaim the lumber for reuse. Clean wood is processed for mulch. B-wood is processed into boiler fuel, mixed with coal and used to power cement kilns and cogeneration plants.

- Plastics are baled and shipped off for processing and cleaning. The materials are separated by type, ground and washed repeatedly and eventually extruded and mixed with virgin plastics to make raw plastic products.

- Cardboard is baled and shipped to a mill where it is recycled into new cardboard products.

- Rubble is processed into a variety of fill products.

- Drywall is processed into a soil amendment, fertilizer, and conditioner. The paper is removed by shaker tables and used as animal bedding.

Sorted piles of metal, cardboard, and drywall at the recycling center. photo credit: A. Golen

These efforts reduce our impact on the environment and takes us a step closer to our goal of silver LEED certification for the Wister Center. Click here to see a complete list of our LEED certification efforts.

No Comments